- home

-

our products

-

Special-purpose devices for furnitures

Cutters and cutter heads with bore

Replacement tip router cutters and boring bits

Cylindrical Cuttes With Threathed Shank

Router cutters with cylindrical shank

Drills in solid carbide for CNC

Firewood splitters and circular saws for firewood

Combined Woodworking multifunctions Machine

Moulding, Routing and edge banding

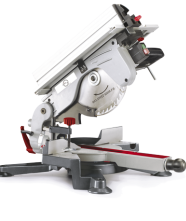

Mitre saw and Combinated table top mitre saw

4 Jaw wood chuck, Interchangeable Point Drive and Live...

Semiprocessed for wood turning

Sculpture and decoration of wood and soft stone

Equipment for shops and factory

Material handling and forklift

Universal table for miter saws and machines

Wood Workbench for shops and Joiner

-

- news

- contacts

Home > Cutters Drills and Blades > Router cutters with cylindrical shank > Concave and convex cutter

Concave and convex cutter

Concave cutter, Convex cutter, Plunging Rounding Over Bits, Rounding Over Bits, Ovolo bits, Beading bits, Rounding over bits for solid surfaces.

Cutters for drains and pits round bottom and edges rounded shank with cylindrical shank, are produced with or without a guide bearing. We also produce drills with the bearing to stondature or trimming floors and sinks Korian ®.

Cutters for drains and pits round bottom and edges rounded shank with cylindrical shank, are produced with or without a guide bearing. We also produce drills with the bearing to stondature or trimming floors and sinks Korian ®.

Type 7

Type 7 Convex cutter

Convex cutter

This is the most widely used profiled cutter, because it can be use in many different workings: it allows you to make grooves and moulded rebatings, to chamfer and to avoid splintering. It is also used in the manufacture of workshop furniture (shelves)

and house furniture (chairs, tables, fornituredoors,……).

The precision and the small tolerances in the production of these cutters enable you to use this cutter along with its negative, Type 6.

Type 7BA

Type 7BA Eagle beak cutter

Eagle beak cutter

This cutter is mostly used to make stair handrails, but it is also used for producing furniture and chairs.

Safety precautions: the cutters with a big diameter produces a big quantity of chips.

Use therefore an exhauster so that the working area is well clear and

clean. Reduce the speed of cutters with Ø 65 mm to 1 8.000 turns/minute.

Type 7CK

Type 7CK Bevel cutter for solid surface

Bevel cutter for corian ®

With this cutter you can round off a corner and join up two inclined surfaces.

It is mostly used in the working of plastic kitchen counter tops and sinks.

Thanks to its special angled ball bearing, which is coated with plastics, the cutter leaves no traces on the workpiece.

Type 6

Type 6 Concave cutter

Concave cutter

These are among the most used cutters; they are produced in special steel, resistent to the abrasion of the wood, and in hard metal, with the most sophisticated technology.

The picture shows an example of a drawer-handle, in which the cutter of type 6 and the cutter of type 7 were used.

Type 6SC

Type 6SC Bearing guided concave cutter

Bearing guided concave cutter

The bearing allows for higher precision and more control over the machine, consequently also a higher safety level while working.

We recommend that you substitute the bearing whenever it gets stuck because of glues or resins, otherwise it will act as guide pivot.

Type 6/2SC

Type 6/2SC Bearing guided concave cutter with step

Bearing guided concave cutter

The bearing allows for higher precision and more control over the machine, consequently also a higher safety level while working.

We recommend that you substitute the bearing whenever it gets stuck because of glues or resins, otherwise it will act as guide pivot.