- home

-

our products

-

Special-purpose devices for furnitures

Cutters and cutter heads with bore

Replacement tip router cutters and boring bits

Cylindrical Cuttes With Threathed Shank

Router cutters with cylindrical shank

Drills in solid carbide for CNC

Firewood splitters and circular saws for firewood

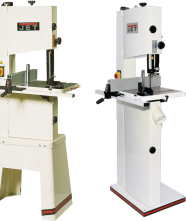

Combined Woodworking multifunctions Machine

Moulding, Routing and edge banding

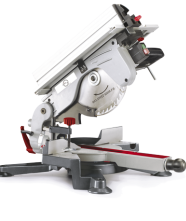

Mitre saw and Combinated table top mitre saw

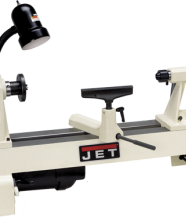

4 Jaw wood chuck, Interchangeable Point Drive and Live...

Semiprocessed for wood turning

Sculpture and decoration of wood and soft stone

Equipment for shops and factory

Material handling and forklift

Universal table for miter saws and machines

Wood Workbench for shops and Joiner

-

- news

- contacts

If you still have the vacuum bag and time to replace them with these systems effiicenti extraction and purification.

Designed for carpentry, interior are machines, they do not scatter your heating, but allow you to have clean air for your health and the elimination of dust that would prevent, for example, to paint your finished furniture.

- Automatic cycle, every 20 Min cleans itself (the pre-set time is changed as a function of the operating conditions), during the step of cleaning the suction is automatically and temporarily decreased.

- Dust extraction and dust from a line up to 4 or 8 cars * 100% of the air is recycled and cleaned of particulate matter.

- Compact and space-saving., In sturdy sheet steel galvanized and epoxy powder coated

- High suction power.

- Preliminary separator chip integrated.

- Good cleaning of filters

- Long filter life, the fabric is treated with a special material and is tested for heavy work, can be washed up to 3 times with industrial washers.

- Low consumption of compressed air, in the phase of the purification filter is inflated for about 1 sec. and only 15 percent of the demand comes from the air compressor, the remaining 85 percent is air present on the spot and is "dragged" by the jet under pressure, so it is sufficient a small compressor.

- Constant yield due to the continuous cleaning of the filters.

- Filter needle felt polyester with surface treatment in category "C" certificate BIA-H3

- Save on heating costs, recovering the indoor air of the laboratory, the heat stays outside and is not dispersed outside.

- Respect the rules inmateria health and safety in the workplace, and EC Directives.

- On wheels for easy movements.

- Swarf cart on wheels, with automatic restraint bag for chips and engagement aspirator.

- It keeps the air clean and breathable

* Machines placed on a same line, suitably connected with pipes and joints, the number of machines contemporary varies by the type of machine to the distance between the latter and the purifier; should be installed a gate valve on each machine to close the vent is not in use.

| Model | JMP 160 | JMP 200 |

| Cod. art 400 V | 195593 T | 195594 T |

| Capacity Sack chips | 280 Lt | 2 x 250 Lt |

| filtering surface | 9 m2 | 13,5 m2 |

| Ø hose | 160 mm | 200 mm |

| Automatic cleaning filter | YES compressed air | YES compressed air |

| Air consumption | 6 bar - 80 Lt/cycle | 6 bar - 80 Lt/cycle |

| Total air flow | 1850 m3/h | 2920 m3/h |

| Vacuum pressure | 2120 Pa | 1900 Pa |

| Dimension mm | 1600x830x1850 | 2307x830x1850 |

| Power | 2,2 Hp (3Kw) | 3 Hp (4Kw) |

| Noise level | 64,9 dB (A) | 75 dB(A) |

| Weight | 288 Kg | 340 Kg |